FINALCAST V/O: High-Strength, Corrosion Resistant Mortar

FINALCAST V/O is a premium, high-strength, corrosion resistant structural liner designed to have a long set time, allowing it to be centrifugally cast to minimize downtime on larger projects such as manhole repair, concrete storm and sanitary sewer pipe repair and renewal.

For use in waterproofing, sealing, structural reinforcement, and corrosion protection of underground sewer pipe and manhole structures that cure in place to form an interior hardened shell.

BENEFITS

- Dense and highly impermeable cementitious liner

- High modulus of elasticity

- Reaches over 6,500 psi

- Concrete gray color

PRODUCT APPLICATION

DOWNLOADS

PACKAGING & COVERAGE

- 50 lb (22.7 kg) bags

- 50 lb (22.7 kg) plastic pails

50 lb (22.7 kg) yields approximately 0.43 cubic feet

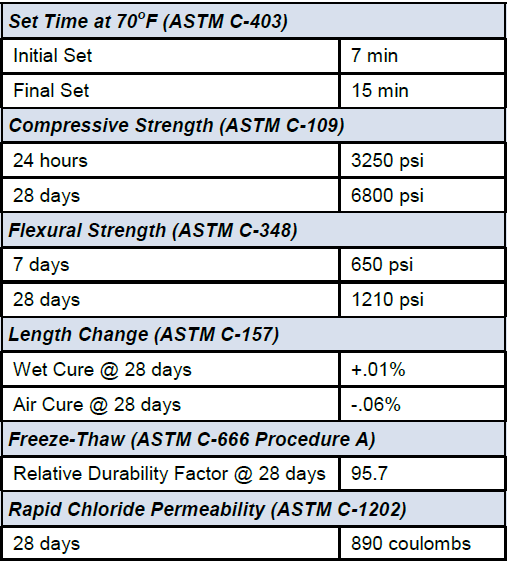

TYPICAL TEST DATA

The data shown is typical for controlled laboratory conditions. Reasonable variation from these results can be expected due to variation in type and quantity of cement, and sand gradation of the mortar mix. When testing the field mixed material, other factors such as variations in mixing, water content, temperature and curing conditions should be considered.